iVision® – Smart Solutions by PeRoBa® Unternehmensberatung GmbH Performing audits in highly complex surroundings is becoming more and more of a challenge. Especially with respect to remote audits, the utilization of new technologies can be a path to reducing efforts and achieving one’s aims more efficiently. The auditors from PeRoBa have also been using data …

Weiterlesen

iVision® – Smart Solutions by PeRoBa® Unternehmensberatung GmbH

Performing audits in highly complex surroundings is becoming more and more of a challenge. Especially with respect to remote audits, the utilization of new technologies can be a path to reducing efforts and achieving one’s aims more efficiently. The auditors from PeRoBa have also been using data glasses, so-called smart glasses for performing audits for quite some time.

iVision® – Remote audits or respectively audits 4.0

With the support of this new and innovative technology, it is possible for us to reduce efforts while conducting remote audits tremendously. An employee of the respective company is then provided with our iVision® software and data glasses.

For example, an auditor is able to see the same things the coworker sees on-site with the aid of this technology. The auditor can actually be located on the other side of the world as well. Communication occurs also through the data glasses. The auditor can communicate with the employee on-site and give them instructions. This coworker performs the audit personally “on-site” instead of the auditor.

Besides, it is possible for the auditor to display visual hints and info and supplementations to the employee. For example, an area the auditor wants to inspect more precisely can be highlighted this way.

Out of this connection, proper integration with our IT system can create an audit report which is generated in an automated manner and which the auditor can further process and complete within an extremely short time.

iVision® – a brand of PeRoBa® Unternehmensberatung (Management Consultancy) GmbH

This is the statement of Dr. Scherb, the managing shareholder of the PeRoBa® Unternehmensberatung (Management Consultancy) GmbH on the successful milestones reached during this year:

„Our team and I are especially glad that the German Patent and Trademark Office granted us the patent for the “device and procedure for visual technical support of manual order picking processes” this year. This functionality serves as the basis for our auditing module with data glasses. As of now, Vision® is also among the best IT solutions for small and medium-sized companies! iVision® was honored with the Best IT of 2018 Innovation Award.

These are the driving forces for us to further develop iVision® and to implement customer requirements in an efficient and pragmatic manner.“

We support you

The team of the PeRoBa® Unternehmensberatung (Management Consultancy) GmbH is happy to stand by your side if you have more questions in this context of if you would like to get recommendations for action. If you have any inquiries or if you would like support, please don’t hesitate to get in touch with us at: https://www.peroba.org/contact/

Your PeRoBa® Unternehmensberatung (Management Consultancy) GmbH Team

The purpose of the 7 quality tools Errors and data can be collected, reasons for errors can be determined and investigated and errors can be prevented and improvements can be made sure by the 7 quality tools. These so-called 7 quality tools were originally put together by Ishikawa for use in quality circles. The 7 …

Weiterlesen

Errors and data can be collected, reasons for errors can be determined and investigated and errors can be prevented and improvements can be made sure by the 7 quality tools. These so-called 7 quality tools were originally put together by Ishikawa for use in quality circles.

The 7 quality tools are simple and efficient tools which will lead to a high degree of efficacy if they are used precisely.

A short description of the 7 quality tools comes next.

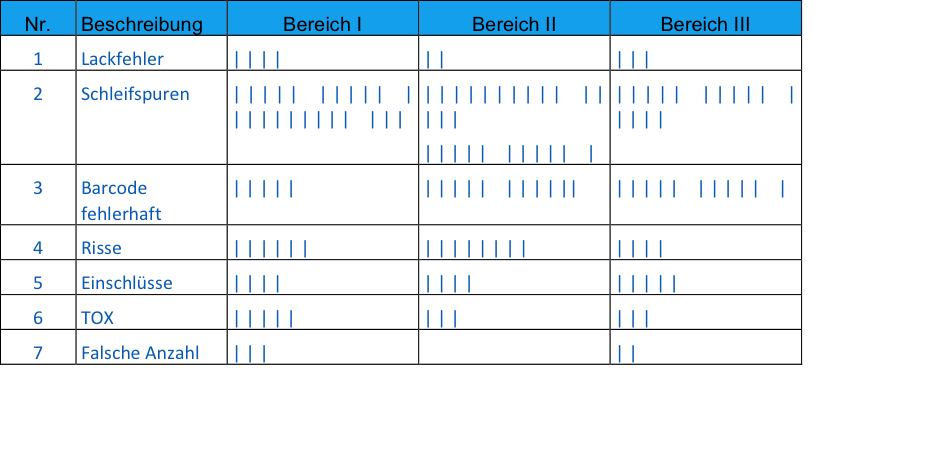

The easiest variety of this consists of a piece of paper with handwritten records on the systematic detection and depiction of different main errors.

Data are put in order depending on the respective frequency of e.g., their occurrence over time. A histogram (a bar chart) is the graphical depiction of the frequency distribution of a quantity of data which were summarized. The depiction helps to classify individual results among a group of the same result or to determine the area where an individual result is expected. Mean values and distributions constitute important extensions of such histograms. The histogram is the basis of further methods like a superimposed bell-shaped curve; the normal distribution.

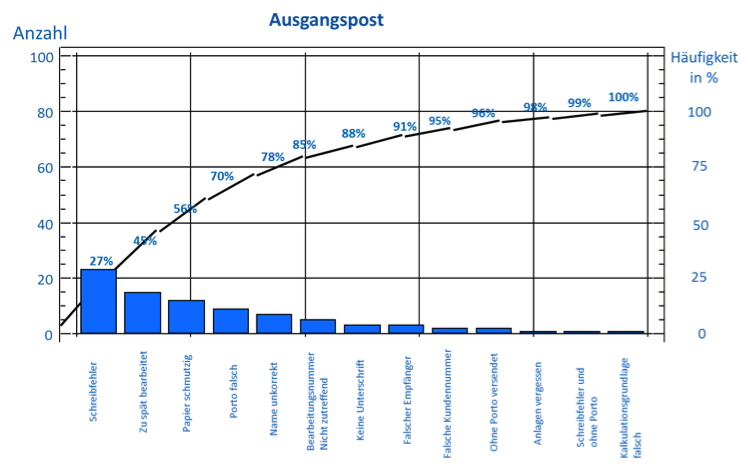

The Pareto depiction is another quality tool. It is a vertical bar chart for the graphical depiction of the reasons for problems. Influences can be arranged here depending on their significance. Important occurrences can be separated from irrelevant ones through the Pareto diagram. Other designations for this are 80-20 distribution or ABC analysis. This tool helps to detect the main reasons better and to process them efficiently.

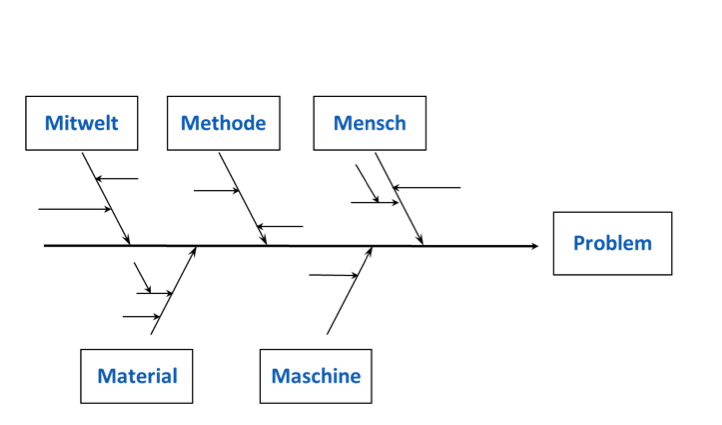

Reasons for the development of problems can be classified and analyzed through a combination of the 5 Ms (machines, methods, materials, man, mission / Mother Nature) or the 7 Ms (machines, methods, materials, man, mission / Mother Nature, measurements, management). That will clarify if the problems respectively the errors might have several reasons which are frequently interconnected.

This is about separating and stratifying data from different sources. Different data are collected in order for them to be treated based on facts.

This is supposed to identify root causes so that improvement measures can be managed.

In many depictions, the method is referred to as brainstorming instead of stratification. Brainstorming is a basic entrance-level technique for looking for possible reasons for problems together in a group of people.

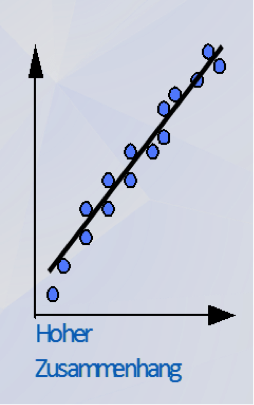

This is the graphical depiction of a correlation between two measured values. Correlations, connections, regularities and tendencies can be read off here.

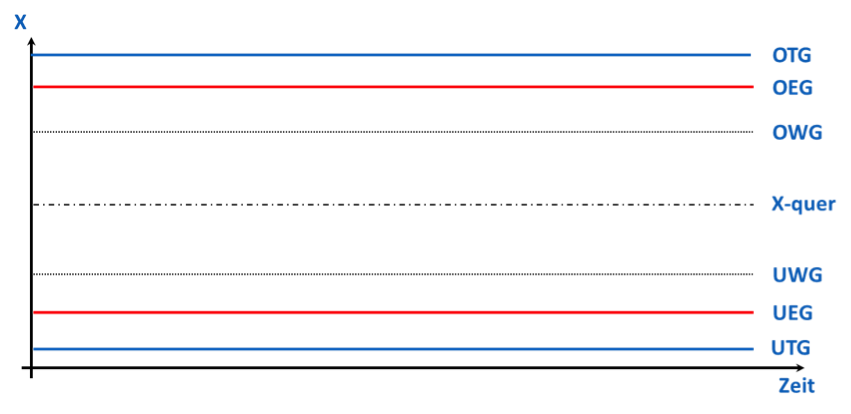

This is an easy quality tool in order to check whether, e.g., a process operates within the tolerance limits and to make sure that it does. The results can be depicted graphically with the aid of the control chart. Furthermore, this tool is excellent for explaining and setting out the standard requirements from chapter 8.1 on “controlled conditions”. More information on that will be posted in one of the next publications.

[/et_pb_text][et_pb_code _builder_version=”4.2.2″ vertical_offset_tablet=”0″ horizontal_offset_tablet=”0″ z_index_tablet=”0″]

What are the 7 Quality Tools (Q7)?

The 7 Quality Tools (abbreviated as Q7, QM Tools) are a collection of proven methods for quality assurance. With them, users can document errors in a strongly targeted manner and collect data, which can be used for avoiding these very mistakes in the future. The methods had already been compiled by Japanese chemist Ishikawa Kaoru in 1943 but they have not lost any of their relevance up to now.

What methods do the 7 Quality Tools include?

The Q7 consist of error collection lists (also data collection sheet), histograms, Pareto charts, Ishikawa diagrams (cause-and-effect diagrams), stratification (colloquially referred to as brainstorming), correlation diagrams and control charts.

What are the M7 (7 Management Tools)?

In contrast to the analytical and quantitative methods of the Q7, the 7 Management Tools (M7) provide a collection of tools which make it possible to structure and analyze verbal information. To present it in a simplified manner, problem solving occurs here through a process of identifying the problem, finding the solution and implementing the solution.

What other QM Tools are there on top of the Q7?

Aside from the classic Q7, FMEA (Failure Mode and Effects Analysis), PPAP (Production Part Approval Process), QFD (Quality Function Deployment) as well as SPC (Statistical Process Control) are utilized most often in practice.